The centrifugal compressor is composed of rotor, stator and bearing. The rotor is the key component of the centrifugal compressor, it can rotate at high speed. The rotor is composed of impeller, main shaft, balance disc, thrust disc and other components. The stator is the fixed component of the compressor, consisting of a diffuser and a curve. Composed of reflux, volute and casing.

The high-pressure centrifugal blower impeller and other parts are sleeved on the main shaft to form a rotor. The rotor is supported on bearings and driven by a power machine to rotate at high speed. The stator includes a casing, a partition, a seal, an air inlet chamber, and a volute chamber. Between the partitions, fixed elements such as diffusers, bends and returners are formed.

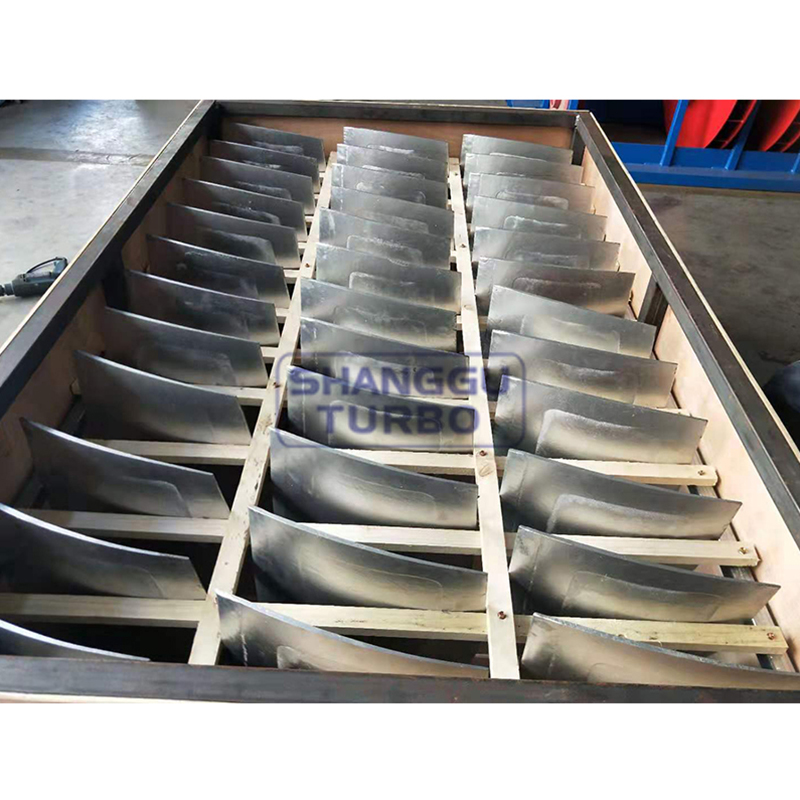

Centrifugal compressors with only one impeller are called single-stage centrifugal compressors, and those with more than two impellers are called multi-stage centrifugal compressors. The pressure and velocity of the gas flow in the working path increase, and the temperature of the gas also increases. The impeller is a part of a centrifugal compressor that can be used for gas. The impeller is a key component of the centrifugal compressor, and there are three types: closed, semi-open and open. When the impeller rotates at high speed, due to the force interaction between the blades and the gas, mainly the centrifugal force, the gas is sucked from the center of the impeller and flows to the outer edge of the impeller along the blade path (the passage between the blades). The impeller does work on the gas, the gas gains energy, and the pressure and speed increase. Then, the gas flows through the diffuser and other channels, the speed is reduced, and the pressure is further increased, that is, the kinetic energy is transformed into pressure energy.

The function of the main shaft is to support the rotating parts (impellers, balance plates, etc.) mounted on it and transmit torque. When determining the size of the design shaft of a turbine fan, not only the strength of the shaft, but also the critical speed of the shaft must be carefully calculated. The so-called critical speed is the speed when the shaft speed is equal to the natural frequency of the shaft. The thrust plate is a part of the thrust bearing fixed on the main shaft. Its function is to act on the thrust bearing through the oil film on the remaining axial force of the rotor, and it also determines the position of the rotor and the fixed element.

Shanggu Turbomachinery (Qidong) Co., Ltd.

Phone: 0086-513-80797666

Mobile:0086-15021856887

Fax: 0086-513-80673989

E-mail: sales@shangguturbo.com

Address: No. 26, Jiangfeng Road, Binhai Industrial Park, Qidong City, Jiangsu Province

powered by :Longding Network

URL:www.shangguturbo.com